DETONATION: THE DEADLY ENEMY

The subject of detonation in engines has been covered in countless articles over the years but it is still a major cause of engine failures. (Refers to spark ignition engines only).

WHAT IS DETONATION?

Detonation is the spontaneous ignition of the fuel/air mixture in some part of the combustion chamber, usually furthest from the spark plug, at some time AFTER the normal ignition of the major part of the charge. Detonation happens when the pressure and temperature in the combustion chamber reaches a level at which the gas in the cylinder ignites instantaneously. This produces an extremely rapid rise in temperature and pressure, which may result in audible “pinging” as the pressure waves strike the combustion chamber wall and piston.

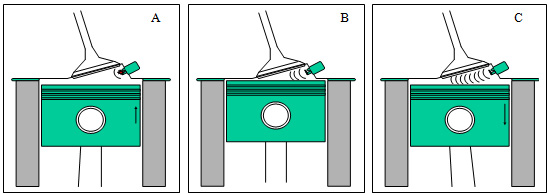

Under normal combustion:

- Piston approaches top dead center and spark plug ignites.

- At top dead center fuel/air mixture begins to burn with flame propagation from spark plug.

- As piston moves down, combustion continues until all of the fuel is burned.

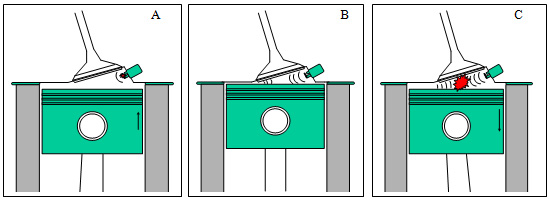

Under detonation conditions

- Piston approaches top dead center and spark plug ignites.

- The rapid build up of temperature and pressure causes the gas mixture furthest from the sparkplug to ignite. This secondary flame is moving towards the primary flame front.

- Both flame fronts meet, which causes an extremely high rate of pressure rise. The temperature of all surfaces in the combustion chamber will rise rapidly. Because the piston is near top dead center the resultant shock wave is massive.

Because the air fuel mixture is burning on two fronts which are approaching each other, the pressure and the rate of pressure rise in the cylinder will be much greater than if there was only one flame front under normal combustion conditions.

To put it simply, there is an explosion in the combustion chamber rather than controlled combustion. A knocking or “pinging” noise may be heard at low speeds but at high speeds detonation may not be audible especially in performance or competition engines, which may have performance exhaust systems and may be noisier anyway.

WHAT ARE THE EFFECTS OF DETONATION?

Different engines with different shaped combustion chambers may have different responses to detonation but the following are probable effects:

Pistons: Pistons will be subjected to the full force of the explosion. Depending upon their design and strength the crowns may crack or break, the ring lands will probably break unless they are over-designed for normal operation, and the skirts will scuff (most often on the thrust sides only). Also the piston skirts may crack and break, again on the thrust side as a result of the load being nearly doubled compared to normal operation. The crowns may be eroded either on the edges or more generally. Other possible effects are pin boss cracking or scuffing, pin breakage, top land scuffing and in extreme cases the piston crown will melt.

Usually, but not always, the hardness of the crown of the pistons will be reduced as a result of the higher temperatures. It is often possible in failure investigations to obtain evidence that detonation has been occurring if the crown hardness has dropped a significant amount compared to the hardness of the piston lower boss area, which runs a lot cooler.

Rings: The top rings are also subjected to the full force of detonation. If the rings are made from regular grey flake cast iron they may break, often into many pieces. If the rings are chromium plated they may scuff against the bores. If they are molybdenum inlaid the molybdenum may flake out. The increased temperatures will lead to the ring gaps getting smaller than normal and depending on the initial gap they may even butt. This can lead to seizure and land breakage. In any event while detonation is occurring the oil consumption and blow-by of the engine will be excessive since the rings will not function correctly. Power output therefore will also be reduced.

Head Gaskets: Detonation may nearly double the force applied to the head bolts or studs. This can lead to gas leakage past the bore binders of the gasket because the higher loads cause the clamping pressure on the gasket to be reduced. In addition the bore binders (which are usually steel or stainless steel) may be eroded and will suffer from mechanical failure.

Bearings: Detonation problems can result in fatigue failure of the rod bearings. However the advantage of modern bearings materials with very high fatigue resistance has lessened the frequency of bearing failure due to detonation.

WHAT CAUSES DETONATION?

Detonation is prevented by using a fuel that has an octane rating high enough to suit the particular engine compression ratio. Conversely detonation is avoided by building an engine with the compression ratio to suit the octane value of the fuel which you are going to use. The tendency for an engine to detonate is not only governed by the compression ratio. Combustion chamber designs, surface area to volume ratio, gas turbulence, squish and spark plug location are also important factors.

The optimum sparkplug location in the combustion chamber is that which ensures that the hottest gas will burn first. Optimum sparkplug location is often not possible in certain engine designs, and less than perfect sparkplug locations are often substituted by the manufacturers. Sparkplug location, combustion chamber shape and engine design cannot be easily changed. However many other factors can be easily changed.

Factors that will increase the tendency for a given engine to detonate are as follows:

- Over advanced ignition (static)

- Excessively heated intake charge

- Inoperative advanced/retard mechanism in the distributor

- Incorrect ignition advance

- Retarded ignition

- Excessive boost

- Excessive vacuum advance at part throttle

- Pre-ignition

- Lean air/fuel mixture

- Leaking intake manifold

- General or localized overheating

- Heat range of spark plugs too high

- Old or contaminated fuel

- Cross firing due to parallel ignition leads taped together

- Engine management system and/or sensors inoperative

- Excessive high compression ratio

- Excessive build up of carbon deposits which effectively raise compression ratio

- Excessive stock removed from either block or cylinder head which will effectively raise compression ratio

- A combination of any or all of the above in conjunction with a marginally high compression ratio or marginally low octane rating fuel

All of the above can be major contributing factors but even if none are present if the fuel used is not high enough in octane for the compression ratio of the engine there is a strong possibility that detonation will occur.

WHAT ABOUT PRE-IGNITION?

Pre-ignition is where a charge is not fired by the spark plug electrically, by a hot spot in the combustion chamber. This generally occurs BEFORE ignition of the sparkplug! This can be a result of hot spots in the chamber (glowing deposits or valve edges, spark plug electrodes etc.) and may result from detonation occurring. Pre-ignition is like detonation in that it is very destructive as it also causes massive increases in combustion chamber pressures, pressure rise rates and temperatures. It causes engines to run on after the ignition is switched off and often results from use of lower octane petrol than the engine requires.

It is also caused by incorrect heat range spark plugs (too hot) and/or lean mixtures. If allowed to continue it can lead to localised melting of the piston very quickly. Failures have been encountered within seconds in instances where high performance competition engines have been run under full power conditions on their “warm up” spark plugs!